How Do Pan Head Self Drilling Screws Improve Efficiency in Metal-to-Metal Fastening?

2025.05.19

2025.05.19

Industry news

Industry news

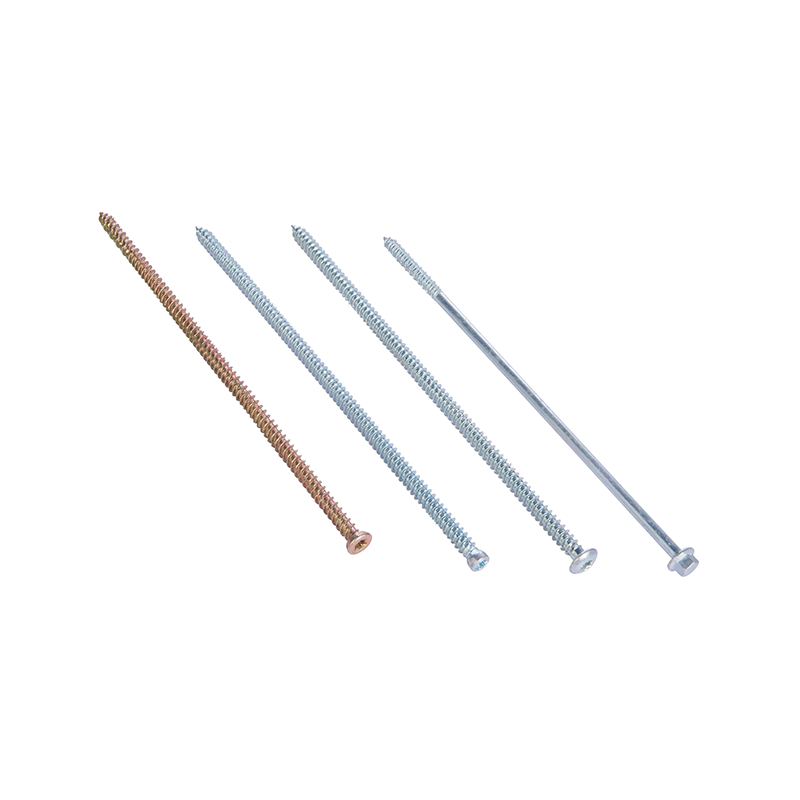

Pan Head Self Drilling Screws offer significant benefits that improve efficiency in metal-to-metal fastening. These screws are designed to address several challenges typically associated with traditional fastening methods, such as the need for pre-drilling, installation time, and securing a strong connection.

One of the most prominent advantages of Pan Head Self Drilling Screws is their ability to eliminate the need for pre-drilling. Unlike regular screws that require a pilot hole to be drilled before installation, self-drilling screws come with a specialized tip that allows them to drill their own hole as they are driven into the material. This means that installers don’t need to spend time setting up a separate drilling step, which speeds up the entire process. In applications where metal-to-metal fastening is common, such as construction, automotive, or manufacturing, this ability to skip the pre-drilling stage can significantly cut down on time and reduce the number of tools required.

This leads directly to faster installation. Since Pan Head Self Drilling Screws combine drilling, tapping, and fastening all in one motion, the process becomes much quicker compared to traditional methods that would typically require multiple steps and tools. In fact, with these screws, the need to switch between a drill bit and a screwdriver or impact driver is eliminated. This streamlined process can be especially beneficial in large-scale operations or construction projects where time is money. The reduced labor time results in a faster overall completion of tasks, making it an attractive choice for both contractors and manufacturers looking to increase productivity.

In addition to saving time, Pan Head Self Drilling Screws offer enhanced precision and control. Their self-drilling design ensures that the screw goes in at the correct angle and depth, providing a consistent result. This built-in feature reduces the chances of misalignment or threading problems that can occur when drilling and screwing separately. This not only improves the quality of the fastening but also reduces the need for adjustments or rework. The accuracy of these screws helps ensure that each connection is secure and strong, which ultimately reduces the likelihood of failures in metal-to-metal applications.

Another advantage is the reduction in tool changes and setup time. With Pan Head Self Drilling Screws, installers can use standard power tools, such as impact drivers or drills, to complete the job. There’s no need for special equipment or additional setup for pre-drilling. This eliminates the downtime often caused by switching between tools, allowing workers to maintain a smooth workflow. In environments where speed and minimal disruption are critical, this feature is particularly valuable. The ability to complete a task with minimal tool changes helps to maintain the momentum of the work, which is important in high-pressure or high-volume projects.

The strong and secure fastening capabilities of Pan Head Self Drilling Screws also contribute to overall efficiency. The design of the pan head provides a broad surface area, which helps distribute pressure more evenly across the material. This feature reduces the risk of the screw pulling through the material, ensuring a strong, lasting connection. Since the screws create tight, durable fastenings, the need for re-tightening or replacing screws is minimized. This translates to fewer repairs or maintenance down the road, which saves both time and money in the long run.

While Pan Head Self Drilling Screws may come at a slightly higher cost than regular screws, the time and labor savings they offer can make them a cost-effective choice in many applications. The reduced need for pre-drilling and the faster installation process can lower overall project costs. The long-term reliability of these screws means that they will likely need less maintenance or replacement, further contributing to their overall value. For businesses looking to optimize their operations, the investment in Pan Head Self Drilling Screws is often recouped through the increased speed and efficiency they bring to the fastening process.

English

English русский

русский

Products

Products Tel: 86-574-62101087

Tel: 86-574-62101087 E-mail:

E-mail:  Add: Xiaocao 'e Binhai Industrial Park, Yuyao, Zhejiang, China

Add: Xiaocao 'e Binhai Industrial Park, Yuyao, Zhejiang, China