How Do Chipboard Screws Prevent Material Splitting in Wood?

2026.01.26

2026.01.26

Industry news

Industry news

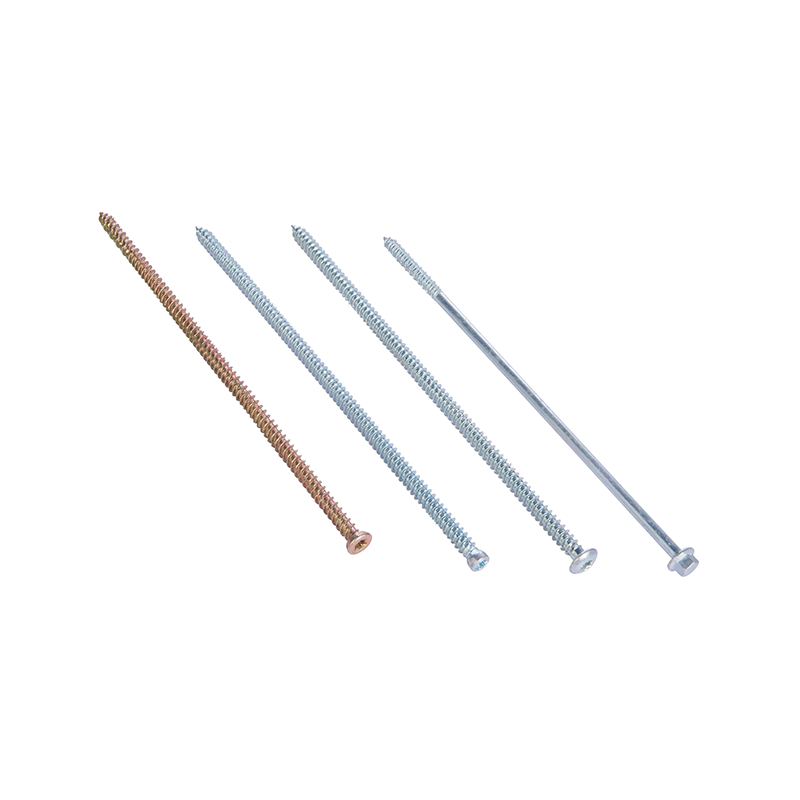

When working with wood, especially engineered woods like chipboard, MDF (Medium Density Fiberboard), or plywood, one of the most common challenges is material splitting during the fastening process. Chipboard screws are specially designed to address this issue. Their unique features minimize the stress applied to the wood, ensuring stronger, cleaner connections without damaging the material.

1. Thread Design for Optimal Grip and Reduced Stress

One of the key features of chipboard screws is their coarse thread design. Traditional screws may have finer threads, which can create high points of pressure when driven into softer materials. This can lead to the wood splitting, especially in brittle materials like chipboard or MDF, which are often more prone to cracking.

The coarse threads of chipboard screws are spaced wider apart and have a deeper cut, which helps spread the force over a larger surface area. This design ensures that the screw creates a firm grip in the wood without concentrating too much pressure on any one spot. This distribution of stress significantly reduces the likelihood of the material splitting.

For example, when the screw is inserted, the coarse threads move the material out of the way more smoothly than fine threads would. This minimizes the risk of cracking or splintering around the hole. The wider thread spacing also helps the screw achieve a better hold on the material, preventing the need for overtightening that could lead to stress and splitting.

| Screw Type | Thread Design | Risk of Splitting |

|---|---|---|

| Chipboard Screw | Coarse, wide-spaced threads | Low |

| Regular Screw | Fine, closely spaced threads | High |

2. Self-Tapping Tip to Reduce Pre-Drilling Stress

Another important feature of chipboard screws is their self-tapping tip. Many chipboard screws are designed with a sharp point that allows them to start drilling into the material without the need for pre-drilling. This is particularly beneficial when working with chipboard or MDF, which can be easily damaged by excessive drilling.

Without a self-tapping tip, screws often require a pre-drilled pilot hole, which, if not done correctly, can cause the wood to crack or splinter. The sharp tip of chipboard screws ensures that they enter the material without putting undue stress on the surrounding wood fibers. This feature also prevents the creation of weak points around the hole that could later lead to splitting, making it especially useful when working with brittle or engineered wood.

Even when pre-drilling is required for tougher woods, the self-tapping tip minimizes the risk of material damage by allowing the screw to cut a clean hole, reducing friction and splitting forces. This allows the screw to pass through the material smoothly without the need for excessive force.

| Feature | Effect on Material |

|---|---|

| Self-Tapping Tip | Smooth entry, reduces risk of cracking and splitting |

| No Pre-Drilling Required | Reduces time and eliminates risk of drilling damage |

3. Smooth Shank for Even Pressure Distribution

Chipboard screws often have a smooth shank, which is the portion of the screw above the threaded area. This part of the screw plays a crucial role in preventing splitting. The smooth shank helps distribute pressure evenly as the screw is driven into the material.

When a screw with a threaded shank is used, it can place concentrated pressure on the material, especially as the threads move through the wood. This concentrated force can lead to cracks, particularly near the surface of the material. The smooth shank on chipboard screws reduces this localized pressure, which is crucial when working with materials like chipboard or MDF, which are more vulnerable to splitting.

Additionally, the smooth shank guides the screw into the wood, allowing the threaded portion to do the work of securing the material without stressing the surrounding fibers. This prevents the screw from binding in the hole and minimizes the risk of material failure.

| Screw Feature | Effect on Material |

|---|---|

| Smooth Shank | Even pressure distribution, prevents localized stress and cracks |

| Threaded Shank | Increases grip but may create localized stress if not designed properly |

4. Blunt, Flat Head Design for Even Load Distribution

The flat head of chipboard screws is designed to distribute the load more evenly across the surface of the material. This prevents concentrated force at the point where the screw contacts the wood, which can otherwise lead to cracks or splits.

For example, screws with a sharp point or a conical head can create localized pressure when driven into wood. This is especially problematic in engineered woods like chipboard, which have layers of compressed material. The blunt or flat head of a chipboard screw applies force across a wider area, creating a stronger hold while preventing the material from cracking under the pressure.

The flat head is especially effective in avoiding damage to the outer layers of engineered woods, which are more susceptible to splitting or tearing. Additionally, the head of the screw is typically designed not to dig too deep into the wood, ensuring that the screw doesn’t create a stress point that could cause the material to fracture.

| Head Design | Effect on Wood |

|---|---|

| Flat Head | Even distribution of force, reduced risk of material damage |

| Sharp or Pointed Head | Increased risk of cracking or surface damage |

5. Reducing Stress Through Controlled Insertion Speed

When using chipboard screws, the speed at which the screw is driven into the material can have a significant impact on whether or not the wood will split. If the screw is driven too quickly, it can apply sudden, excessive pressure on the material, leading to splitting.

Chipboard screws are designed to be used with a moderate driving speed, which helps control the insertion force. Power tools like drills and impact drivers can be adjusted to maintain a steady speed when inserting these screws, ensuring that the material isn’t subjected to too much pressure at any given point. By controlling the speed, the screw enters the material gradually, allowing the fibers to compress evenly rather than snap or break under sudden stress.

This method of controlled insertion helps minimize the risk of cracking, especially in softer woods or engineered woods that are more sensitive to high-pressure forces.

6. Using the Right Type of Chipboard Screw for the Right Material

While chipboard screws are specifically designed to prevent splitting in engineered wood, it’s still important to select the correct screw type for the material you’re working with. For instance, using a chipboard screw that is too large or too small for the material can still result in splitting.

For example, softwoods like pine may require a screw with finer threads to reduce the pressure during insertion, while materials like MDF or particleboard benefit from the coarse threads of a chipboard screw. The screw’s length and gauge should also match the material’s thickness to ensure a strong hold without over-stressing the fibers.

Properly selecting the screw ensures a secure and stable fastening, minimizing the risk of splitting and maximizing the longevity of the bond.

FAQ

1. What is the difference between a chipboard screw and a regular screw?

Chipboard screws have coarser, wider threads designed to prevent splitting in soft or engineered wood, while regular screws typically have finer threads and are better suited for harder woods.

2. Can chipboard screws be used in hardwoods?

Yes, chipboard screws can be used in hardwoods, but for optimal results, it’s important to select the appropriate size and thread type for the specific wood.

3. Do I always need to pre-drill when using chipboard screws?

For softer materials like MDF, chipboard screws often do not require pre-drilling. However, for tougher woods, pre-drilling may be beneficial to avoid stress and splitting.

4. How can I prevent splitting when driving chipboard screws?

To prevent splitting, ensure you use the right size screw for the material and drive it at a moderate speed, avoiding excessive force. Pre-drilling may also help with harder materials.

5. Are chipboard screws suitable for outdoor use?

Chipboard screws are typically not designed for outdoor use unless they are coated for corrosion resistance. For outdoor applications, it is recommended to use screws that are specifically rated for moisture exposure, such as galvanized or stainless steel screws.

References

- “Understanding Wood Fasteners: How Chipboard Screws Prevent Material Damage,” Woodworking Journal, 2021.

- “The Role of Screw Thread Design in Reducing Wood Splitting,” Journal of Wood Technology, 2020.

- “Best Practices for Using Chipboard Screws,” Home Improvement Tools, 2019.

English

English русский

русский

Products

Products Tel: 86-574-62101087

Tel: 86-574-62101087 E-mail:

E-mail:  Add: Xiaocao 'e Binhai Industrial Park, Yuyao, Zhejiang, China

Add: Xiaocao 'e Binhai Industrial Park, Yuyao, Zhejiang, China