How to choose the safest and most reliable expansion anchors and rubber plugs for hollow brick walls?

2025.12.01

2025.12.01

Industry news

Industry news

Guide to Anchoring Hollow Brick Walls: Prioritizing Safety and Reliability

Hollow brick walls (or hollow masonry units) are fundamentally different from solid concrete or solid wood walls due to their internal cavities. When choosing anchors, you must not use traditional expansion bolts designed for solid materials, as they cannot expand effectively into the void, often leading to anchor failure and potential wall damage.

The core principle for selecting anchors for hollow brick walls is to distribute the load over a larger inner surface area or chemically bond the anchor to the wall material.

Three Most Reliable Anchor Types for Hollow Walls

For the high strength and reliability required in hollow brick walls, here are the three most recommended anchoring systems:

1. Toggle Bolts (or Toggle Anchors)

- Working Principle: This is one of the strongest anchors for hollow walls. It consists of a bolt and a foldable wing (or toggle) that passes through the drilled hole. Once inside the wall cavity, a spring causes the wing to deploy. As the bolt is tightened, the deployed wing presses firmly against the inner surface of the brick, distributing the pulling force over a large area.

- Reliability Advantage: Offers excellent pull-out and shear resistance because the load is not concentrated at a single point but spread across the entire wing.

- Best For: Heavy-duty mounting, such as large flat-screen TV mounts, heavy shelving units, kitchen cabinets, or items subjected to dynamic loads.

2. Molly Bolts (or Hollow Wall Anchors)

- Working Principle: A Molly anchor is a metal sleeve anchor. During installation, the anchor body is inserted into the hole. By tightening the central screw, the metal sleeve on the back side of the wall collapses and expands like an umbrella, forming a stable “cup” or “petal” shape inside the wall cavity.

- Reliability Advantage: Simple and stable installation. Often, the screw can be removed and reinserted later without compromising the main anchor body which remains securely in the wall.

- Best For: Medium to heavy-duty mounting, such as large mirrors, bathroom towel bars, curtain rods, or medium-sized decorative shelves.

3. Chemical Anchors (or Resin Anchors)

- Working Principle: This is the highest strength anchoring method. It uses a two-part resin or epoxy compound. During installation, a custom nylon mesh sleeve is often inserted into the hole (to prevent the resin from flowing away into the deep cavity), the chemical compound is then injected into the sleeve, and finally, a threaded rod or rebar is inserted. Once cured, the compound forms a powerful chemical bond and mechanical interlock with the rod, the mesh, and the surrounding brick cavities.

- Reliability Advantage: Provides extremely high load-bearing capacity, vibration resistance, and durability, making it the best alternative to mechanical anchors in hollow walls.

- Best For: Extremely heavy, structural, or permanent installations, such as outdoor air conditioner brackets, awnings, heavy handrails, and applications where the highest level of safety is required.

Usage and Limitations of Simple Plugs

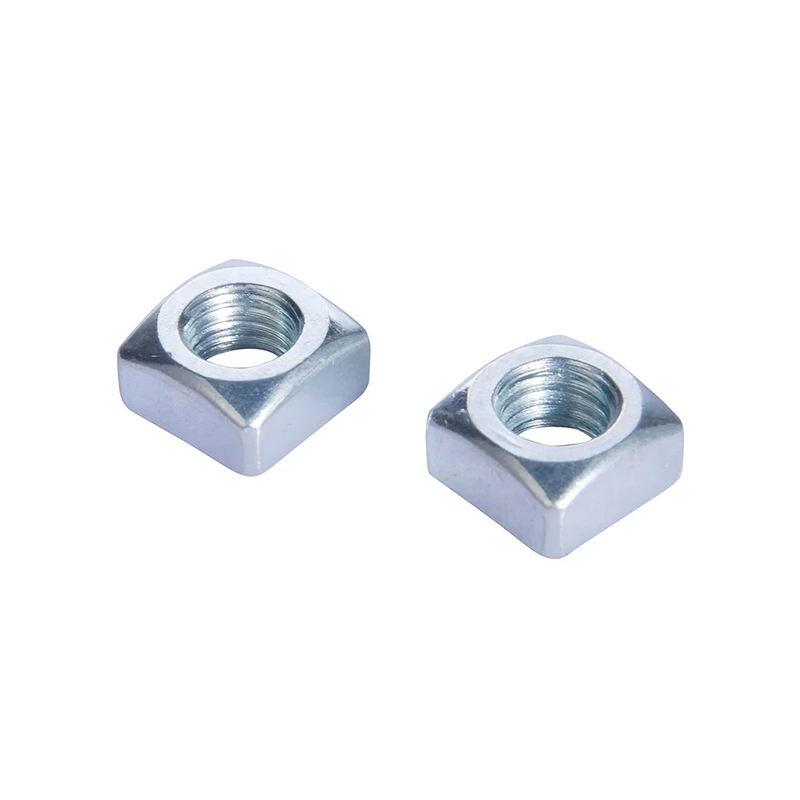

For very light items, expansion plugs can be used, but you must choose types specifically designed for hollow masonry.

- Suitable Type: You should choose Universal Nylon Plugs, rather than simple straight plastic plugs designed for solid walls. These nylon plugs are designed to “knot,” twist, or deform significantly in the cavity as the screw is driven in, increasing the contact area and friction with the wall.

- Load Limit: Only suitable for extremely light loads, such as small picture frames or lightweight decorative items.

- Safety Tip: If the plug spins freely when you try to drive the screw in, the wall material is too weak or the hole diameter is incorrect. You must immediately switch to one of the heavy-duty anchor types listed above.

Hollow Brick Wall Anchor Reliability Comparison Table

| Anchor Type | Applicable Load Level | Anchoring Principle | Advantages | Disadvantages |

|---|---|---|---|---|

| Toggle Bolts | Heavy Duty | Mechanical toggle/wing, large bearing surface on inner face | Extremely high pull-out strength; suitable for various cavities | Requires a large hole; wing may drop if bolt is removed; requires space for wing deployment |

| Molly Bolts | Medium to Heavy Duty | Mechanical expansion, sleeve collapses inside the cavity | Easy to install; screw can be repeatedly removed and reinserted | Lower ultimate load than toggle bolts; requires sufficient cavity depth |

| Chemical Anchors | Extremely Heavy Duty | Chemical bonding and mechanical interlock (cured resin) | Highest load capacity; excellent anti-vibration; no expansion stress | Long curing time; higher cost; permanent; higher installation skill required |

| Universal Nylon Plugs | Light Duty | Friction and internal knotting/deformation | Low cost; fast installation | Low load capacity; prone to failure if brick is fragile |

Final Safety Considerations for Anchor Selection

When finalizing your choice, follow these crucial steps to ensure safety and reliability:

- Determine Load Type and Direction: Distinguish between pure tension (like a ceiling suspension), shear force (like a vertical picture), or leveraged force/moment (like shelves projecting from the wall). Leveraged forces are typically the most destructive and require the highest-rated anchors.

- Over-Engineering Capacity: Always select an anchor with an ultimate rated capacity at least 2-3 times higher than the actual weight of the object, to account for material aging, installation errors, and unforeseen impact loads.

- Follow Manufacturer’s Instructions: Strictly adhere to the anchor manufacturer’s specifications for drilling diameter, drilling depth, and tightening torque. Incorrect drilling or torque is a common cause of anchor failure.

English

English русский

русский

Products

Products Tel: 86-574-62101087

Tel: 86-574-62101087 E-mail:

E-mail:  Add: Xiaocao 'e Binhai Industrial Park, Yuyao, Zhejiang, China

Add: Xiaocao 'e Binhai Industrial Park, Yuyao, Zhejiang, China