What is the working principle of torque transmission of products under the category of Threaded Hex Bolts?

Yuyao Cili Machinery Co., Ltd., as an expert in the field of fasteners, focuses on the design and production of self-drilling screws, wood screws, and window expansion screws. We are well aware that quality is the foundation of the survival of the enterprise. Therefore, from the procurement of raw materials to the delivery of finished products, every link strictly follows international standards and strives to be perfect.

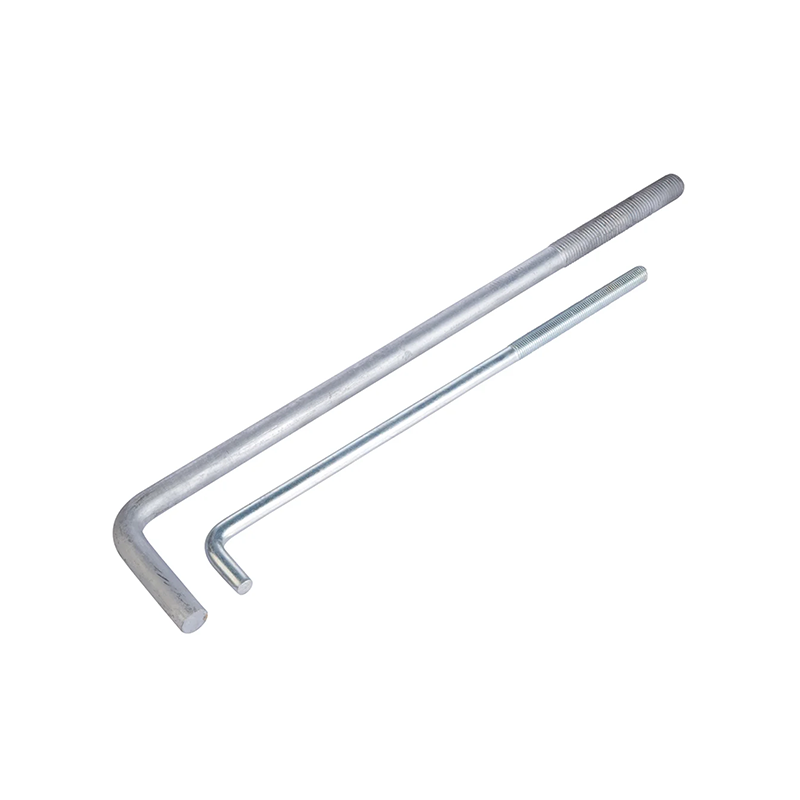

Below we will focus on the Threaded Hex Bolts we produce. This type of bolt is widely used in industries such as construction, machinery manufacturing, and automobile repair. It has good strength and stability, especially in terms of torque transmission.

1. The structure of Threaded Hex Bolts consists of a hexagonal head and a threaded rod body.

Hexagonal head: The hexagonal head design enables the bolt to easily apply torque through tools such as wrenches. The six flat surfaces provide multiple points of contact for the tool to ensure that the torque can be smoothly and effectively transmitted to the threaded part.

Threaded rod body: The threaded part enables the bolt to firmly fix the two workpieces when it is screwed into the screw hole or matched with the nut. This thread design not only increases the contact area, but also ensures the stability of the connection through friction.

2. The torque transmission of Threaded Hex Bolts mainly depends on the interaction between the hexagonal design of the bolt head and the thread. In actual operation, the transmission of torque involves several important steps and factors.

Application of torque: When we use a wrench or other tool to apply torque, the hexagonal head enables the tool to fit the bolt tightly, avoid slipping and accurately transmit the force to the bolt shank. The benefit of this design is that it makes the force evenly distributed and does not concentrate on one side, thereby reducing the wear of the bolt head.

Friction of threads: When the bolt starts to rotate, the threaded part generates friction with the screw hole or nut. This friction is the key factor to prevent the bolt from loosening. The greater the torque applied, the greater the friction between the threads, which ensures that the bolt remains stable under high stress.

Generation of tensile force: When the bolt is tightened, the rotation of the thread gradually stretches the bolt shank. Tensile force is the source of the preload provided by the bolt, and the degree to which the bolt shank is stretched determines the clamping force between the joint surfaces. Within a certain torque range, the greater the tensile force, the greater the contact force between the connecting parts, and the stronger the connection.

Balance between torque and tensile force: In order to ensure that the bolt will not be overstretched or loosened due to insufficient torque during use, the balance between torque and tensile force is particularly important. Excessive torque can cause the bolt shank to be overstretched or even broken, while insufficient torque cannot provide sufficient clamping force. Therefore, in actual operation, the reasonable application of torque is crucial to the stability and safety of the bolt.

3. In the torque transmission process of Threaded Hex Bolts, several factors have a significant impact on its efficiency and stability.

Material selection: Bolts of different materials have different torque transmission capabilities. High-strength alloy steel or stainless steel bolts perform better when subjected to high torque, while softer carbon steel bolts may deform or break under high torque. Therefore, choosing the right material is the basis for ensuring that the bolt can effectively transmit torque in the application.

Thread precision: The manufacturing precision of the thread directly affects the efficiency of torque transmission. If the thread gap is too large, the torque will lose some energy during the transmission process, resulting in insufficient tightening force. The precision-made threads can ensure that the torque is efficiently transmitted to the bolt body and form a reliable tightening effect.

Use of lubricants: In some high-stress applications, in order to reduce the friction loss between the threads, the use of lubricants can improve the efficiency of torque transmission. Lubricants can reduce the friction between the bolt and the nut or the screw hole, so that the torque can be more effectively converted into the tensile force of the bolt, thereby enhancing the tightening effect.

Calibration of torque tools: The accuracy of the tool that applies torque is crucial for the tightening of Threaded Hex Bolts. The use of calibrated torque wrenches or other precision tools can ensure the accuracy of torque application and avoid bolt failure caused by excessive or insufficient force.

4. In practical applications, the torque transmission performance of Threaded Hex Bolts makes it widely used in various industrial occasions. Especially in the demand for high-strength connections, this type of bolt performs well with its excellent shear and tensile resistance. Whether it is bridge construction, mechanical assembly, or automobile manufacturing, Threaded Hex Bolts can provide reliable tightening effects.

Application in building structures: In the field of construction, Threaded Hex Bolts are often used for steel structure connections. The weight of building materials and the stress of the external environment require bolts to have good torque transmission capabilities to ensure the overall stability of the building structure.

Application in mechanical equipment: In the assembly of mechanical equipment, the high strength and torque transmission capabilities of Threaded Hex Bolts make them key fasteners. The vibration and impact force during the operation of the equipment will cause stress on the bolts. High-quality Threaded Hex Bolts can effectively resist these stresses and prevent the equipment from loosening.

Application in the automotive industry: The reliability of Threaded Hex Bolts is crucial in the automobile manufacturing process. The dynamic load during the driving of the car exerts huge shear and tensile forces on the bolts. Therefore, the torque transmission capacity of the bolts determines the safety and durability of the vehicle.

Yuyao Cili Machinery Co., Ltd. is committed to providing high-quality Threaded Hex Bolts to customers around the world. Through advanced production equipment, strict quality inspection processes and rich manufacturing experience, we can ensure that every bolt product can perform well in high-strength applications. Whether it is construction, machinery or automotive industry, our Threaded Hex Bolts' superior performance in torque transmission makes it the only choice for high-strength fastening needs.

English

English русский

русский

Products

Products Tel: 86-574-62101087

Tel: 86-574-62101087 E-mail:

E-mail:  Add: Xiaocao 'e Binhai Industrial Park, Yuyao, Zhejiang, China

Add: Xiaocao 'e Binhai Industrial Park, Yuyao, Zhejiang, China