Advantages of mechanical anchoring of concrete screws

Concrete screws achieve a tight connection with the concrete substrate through its unique mechanical locking principle. This connection method not only has extremely high load-bearing capacity, but also remains stable under long-term load. Compared with traditional anchoring methods, concrete screws can disperse and transmit loads more effectively, thereby ensuring the overall stability and safety of the building structure. This high bearing capacity and stability are particularly important in natural disasters such as earthquakes and wind disasters, as they can effectively resist external forces and protect the safety of buildings.

The installation process of concrete screws is relatively simple and quick, and does not require complex construction techniques and equipment. Generally speaking, anchoring is achieved simply by drilling holes in the concrete substrate and then driving screws into the holes. This installation method not only saves a lot of manpower and material costs, but also shortens the construction period and improves construction efficiency. Especially in large-scale engineering projects, the mechanical anchoring effect of concrete screws can significantly speed up the construction progress and reduce construction costs.

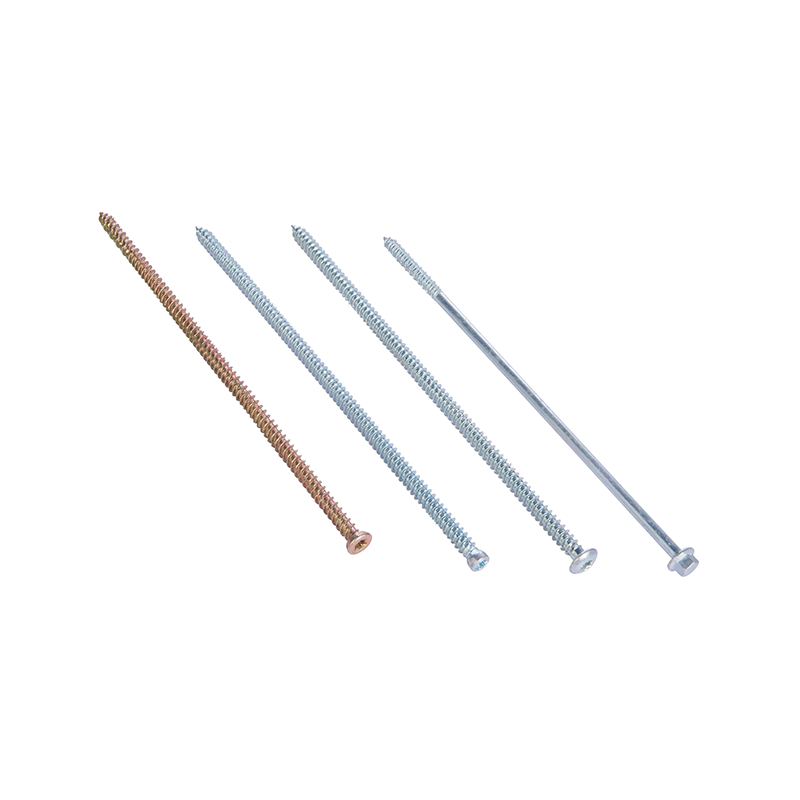

Concrete screws have good material adaptability and can be widely used in different types of concrete substrates. Whether it is ordinary concrete, high-strength concrete or lightweight concrete, concrete screws can achieve effective connections through their mechanical anchoring effect. In addition, concrete screws are also suitable for various scenarios such as the connection of steel structural members and concrete structural members, the reinforcement and fixed connection of steel plates in concrete structures, etc. This wide range of material adaptability makes concrete screws extremely valuable in construction projects.

Concrete screws are made of high-quality materials for extreme durability and reliability. Its surface has been specially treated to effectively resist the effects of adverse factors such as corrosion and wear. In addition, the mechanical anchoring effect of concrete screws also has a self-locking function, which can prevent loosening and falling off to a certain extent. This durability and reliability not only extends the service life of the concrete screws, but also ensures the long-term stability and safety of the building structure.

Compared with traditional anchoring methods, the mechanical anchoring effect of concrete screws is more environmentally friendly. Since there is no need to use chemical materials such as adhesives, there is no environmental pollution. At the same time, the installation process of concrete screws is relatively simple and fast, which can save a lot of energy and resource consumption. This green and environmentally friendly feature is in line with current society's requirements for sustainable development and is conducive to promoting the green transformation and upgrading of the construction industry.

Yuyao Cili Machinery has a full set of advanced production equipment, including wire drawing machines, annealing and cold-beating equipment, clamping devices and rolling machines. These equipments ensure that every production link from raw materials to finished products can reach the top level of the industry. Through precise machining and heat treatment processes, the strength, toughness and corrosion resistance of the screws have been significantly improved, providing a solid foundation for the mechanical anchoring of concrete screws.

English

English русский

русский

Products

Products Tel: 86-574-62101087

Tel: 86-574-62101087 E-mail:

E-mail:  Add: Xiaocao 'e Binhai Industrial Park, Yuyao, Zhejiang, China

Add: Xiaocao 'e Binhai Industrial Park, Yuyao, Zhejiang, China