What factors affect the load-bearing limit of products in the wire screw hooks category?

Yuyao Cili Machinery Co., Ltd. is located on the south bank of the scenic Hangzhou Bay Cross-sea Bridge. It occupies a unique geographical location and has become an important link in the economically prosperous triangle area connecting Shanghai, Hangzhou and Ningbo. The transportation network here is well-connected, providing a solid foundation and unlimited possibilities for the company's rapid development. The WIRE SCREW HOOKS series is one of our company's products. The following will introduce the factors that affect the load-bearing limit of products under the WIRE SCREW HOOKS category.

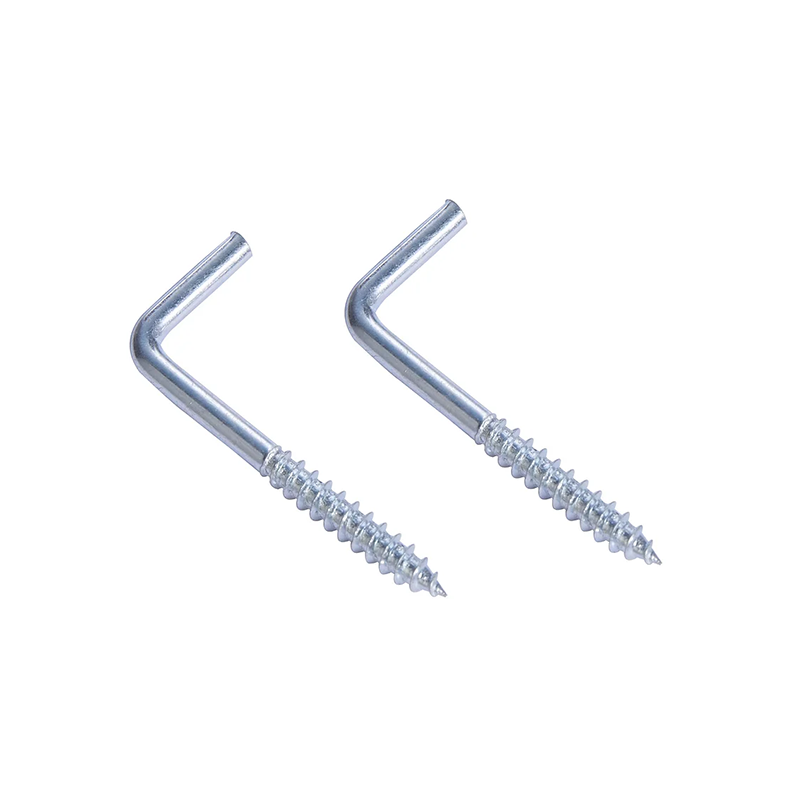

WIRE SCREW HOOKS are a common fastener that is widely used in home, industrial and commercial environments. They are usually made of metal and have a spiral hook body and threaded part that can effectively fix and hang objects. Although wire spiral hooks perform well in various applications, their load-bearing capacity is affected by a variety of factors, which need to be fully considered to ensure the safety and reliability of use.

1. The influence of material type on load-bearing limit

The load-bearing capacity of wire spiral hooks is first affected by the material used. Different metal materials have different strengths and durability, so choosing the right material is essential to meet specific load-bearing needs.

Carbon steel: Carbon steel is a common material for making wire spiral hooks, and is widely used due to its high strength and good processing properties. Carbon steel spiral hooks can provide high load-bearing capacity under normal conditions. However, carbon steel is susceptible to corrosion, so surface treatments such as galvanizing or spraying are usually required to improve its corrosion resistance. Improper treatment or long-term exposure to moisture may cause its load-bearing capacity to decrease.

Stainless steel: Stainless steel spiral hooks are suitable for a variety of harsh environments due to their excellent corrosion resistance and high strength. Stainless steel hooks can maintain their strength and stability in wet or corrosive environments, making them suitable for outdoor or industrial applications. The use of stainless steel materials can significantly increase the load-bearing capacity of spiral hooks, especially in situations where long-term durability is required.

Aluminum alloy: Aluminum alloy is suitable for some light-load applications due to its light weight and corrosion resistance. Although the load-bearing capacity of aluminum alloy spiral hooks is generally lower than that of carbon steel and stainless steel, they perform well in applications that require lightweight, such as home decoration or the hanging of light equipment. Aluminum hooks can also be treated to improve their strength and durability.

2. The impact of thread design on load-bearing capacity

The thread design of the wire spiral hook has a direct impact on its load-bearing capacity. The shape, depth and pitch of the thread will affect the grip and stability of the hook.

Thread depth: The depth of the thread is one of the key factors affecting the load-bearing capacity of the wire spiral hook. Hooks with deeper thread depth can provide stronger grip, thereby improving their load-bearing capacity. Deeper thread design can form a stronger connection with the substrate during installation, reducing the pull of the load on the hook.

Thread pitch: The pitch of the thread also affects the load-bearing capacity of the hook. Threads with larger pitches can provide better load dispersion, thereby improving the overall stability of the hook. In some applications, fine thread design can improve the fixing effect of the hook, but may be limited in load-bearing.

Thread shape: The shape and profile of the thread also affect the load-bearing capacity. Common thread shapes include round threads and square threads. Round threads are usually suitable for ordinary fixing needs, while square threads can provide stronger grip and load-bearing capacity, suitable for heavy-duty applications.

3. The impact of installation method on load-bearing capacity

The installation method of the wire spiral hook is directly related to its load-bearing capacity. The correct installation method can ensure that the hook can fully exert its load-bearing performance.

Drilling size and depth: When installing the wire spiral hook, the size and depth of the drill hole need to match the specifications of the hook. If the drill hole is too large, the spiral hook may not get enough friction; if the drill hole is too small, the hook may not be fully embedded in the substrate, resulting in insufficient load-bearing capacity. Ensuring the accuracy of the drill hole size can improve the fixing effect and load-bearing capacity of the hook.

Tightening force: The tightening force during installation will also affect the load-bearing capacity of the wire spiral hook. Too tight tightening force may cause damage or deformation of the hook, while too loose tightening force cannot ensure close contact between the hook and the substrate. Using appropriate tools and methods can ensure that the tightening force of the hook is in the best state, thereby improving its load-bearing capacity.

Substrate condition: The condition of the substrate has an important influence on the load-bearing capacity of the wire spiral hook. The strength and density of the substrate directly determine the fixing effect of the hook. During installation, it is necessary to ensure that the surface of the substrate is clean and undamaged to improve the load-bearing capacity of the hook.

IV. The influence of the use environment on the load-bearing capacity

The conditions of the use environment will also affect the load-bearing capacity of the wire spiral hook. Different environmental conditions put forward different requirements for the material and design of the hook.

Humidity and corrosion: The load-bearing capacity of the wire spiral hook may be affected in a humid or corrosive environment. Long-term exposure to moisture or chemicals may cause corrosion of the material and reduce the strength of the hook. To cope with these environmental conditions, you can choose materials with corrosion resistance (such as stainless steel) or treat the hook with anti-corrosion.

Temperature changes: drastic changes in temperature may also affect the performance of the wire spiral hook. High temperatures may cause thermal expansion or softening of the material, while low temperatures may make the material brittle. Choosing materials suitable for the temperature change range or making corresponding design improvements can improve the temperature resistance of the hook and maintain its load-bearing capacity.

The wire spiral hook is a widely used fastener, and its load-bearing capacity is affected by multiple factors. Material type, thread design, installation method, and use environment are all important factors in determining the load-bearing capacity of the wire spiral hook. Yuyao Cili Machinery Co., Ltd. is committed to providing high-quality wire spiral hook products and customizing them according to customer needs to meet the load-bearing requirements of various application scenarios. Understanding these influencing factors and optimizing them can ensure the reliability and safety of wire spiral hooks in actual use.

English

English русский

русский

Products

Products Tel: 86-574-62101087

Tel: 86-574-62101087 E-mail:

E-mail:  Add: Xiaocao 'e Binhai Industrial Park, Yuyao, Zhejiang, China

Add: Xiaocao 'e Binhai Industrial Park, Yuyao, Zhejiang, China